Case Three

Application of DSF100 in Mechanical Drive Compartment Covers

Historically Used Sealing Products:

Composite asbestos gaskets

Problems Encountered:

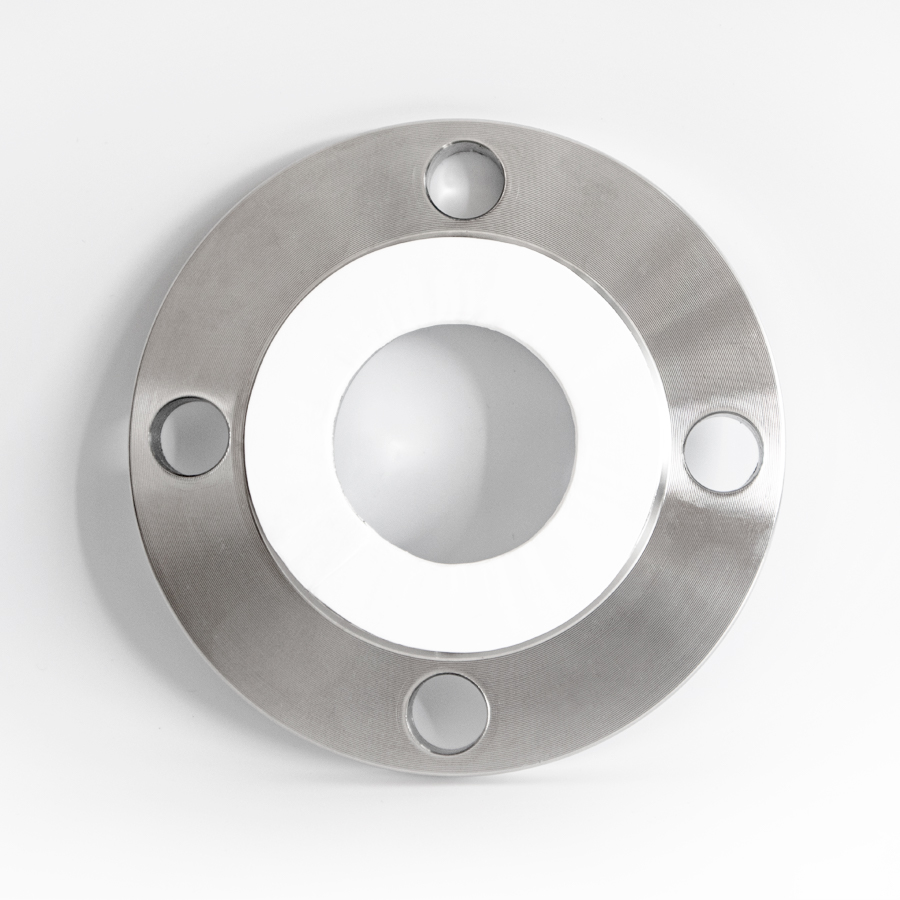

Inside the chamber is equipment that reciprocates at high speeds, there is no pressure difference between the inside and outside of the chamber and it does not need to be airtight, it is necessary to seal the lubricating oil thrown out by the equipment inside the chamber, the composite asbestos gaskets that were used previously were prone to breakage, which led to sealing failure.

Solution and Customer Benefits:

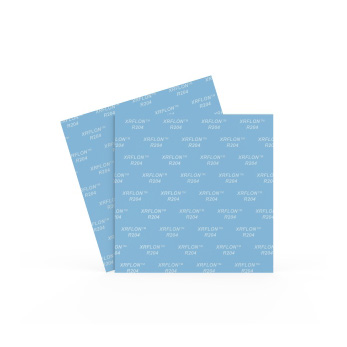

After testing and treatment, the technician recommended installing FlexingSeal® DSF100, a 100% pure PTFE product with material properties such as high and low temperature resistance, acid and alkali resistance, corrosion resistance, resistance to lubrication and self-lubrication.

Secondly, the patented FlexingSeal® DSF100 high-performance sealing tape is highly fibrous internally and has a more homogeneous distribution of microstructure, which gives it better filling properties, creep resistance and, most importantly, consistency in sealing performance.

In addition, FlexingSeal® comes with its own adhesive backing, which makes it easy to install and enables it to follow the shape of the seal, saving gasket fabrication and installation time and reducing downtime costs.