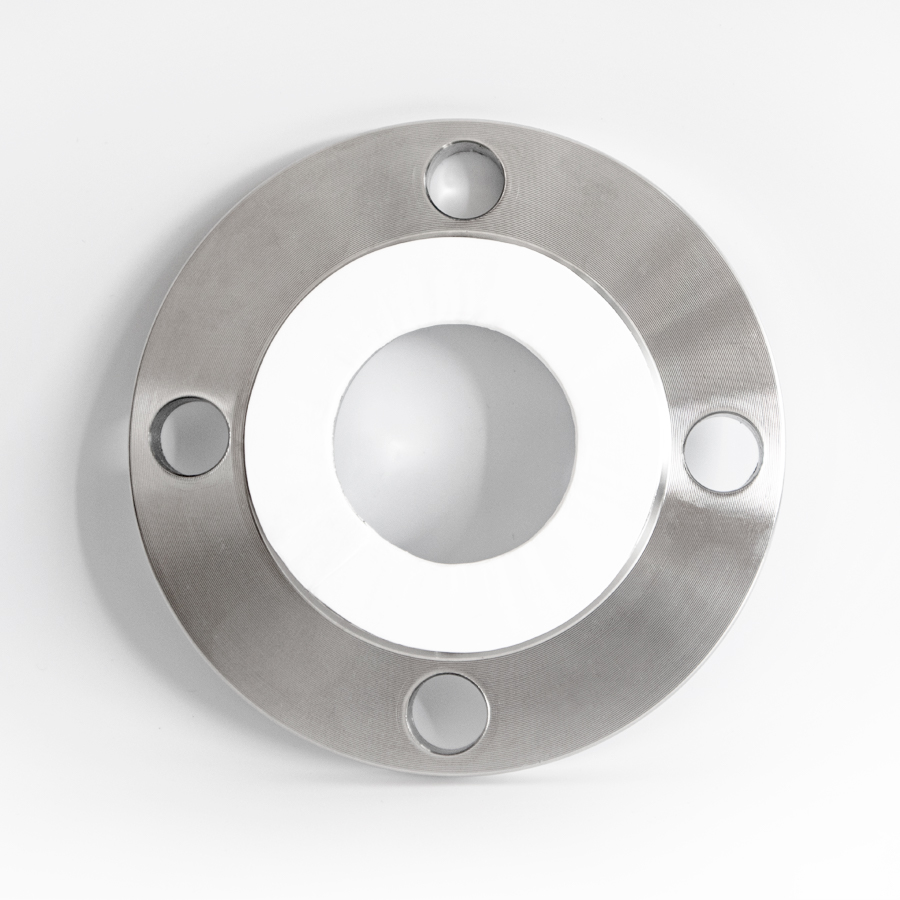

FlexingSeal® SF200

Material:Expanded PTFE

Typical size:Various sizes

Temperature range:-240℃ ~ +260℃

Pressure resistance:0-8 MPa, depending on the installation situations

Chemical Resistance:Chemical resistance to all media of pH 0–14, except molten alkali metals and elemental fluorine

Physiologically inert:Harmless in all recommended applications

Density(ASTM D792):0.6g/cm³~0.9g/cm³

Aging resistance:Under applicable conditions, aging will not occur

Introduction:

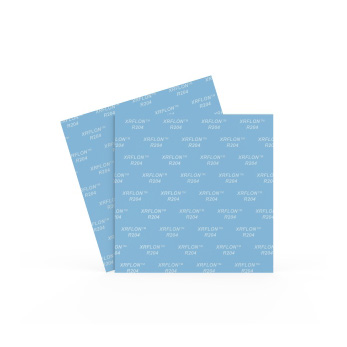

FlexingSeal® enhanced sealing material is a porous structure expanded tape made of 100% pure PTFE. The tape is soft, compressible, and easy to form, making it ideal for applications with damaged sealing interfaces and with low structural strength surface.

FlexingSeal® SF200 is an enhanced sealing material made by special patented technology. Compared with ordinary expanded PTFE tape, SF200 greatly improves the strength of fiber structure, so it has excellent creep resistance and resilience performance.

SF200 can adapt to any shape and size of the sealing interfaces, and achieve long-term reliable sealing.

Advantages:

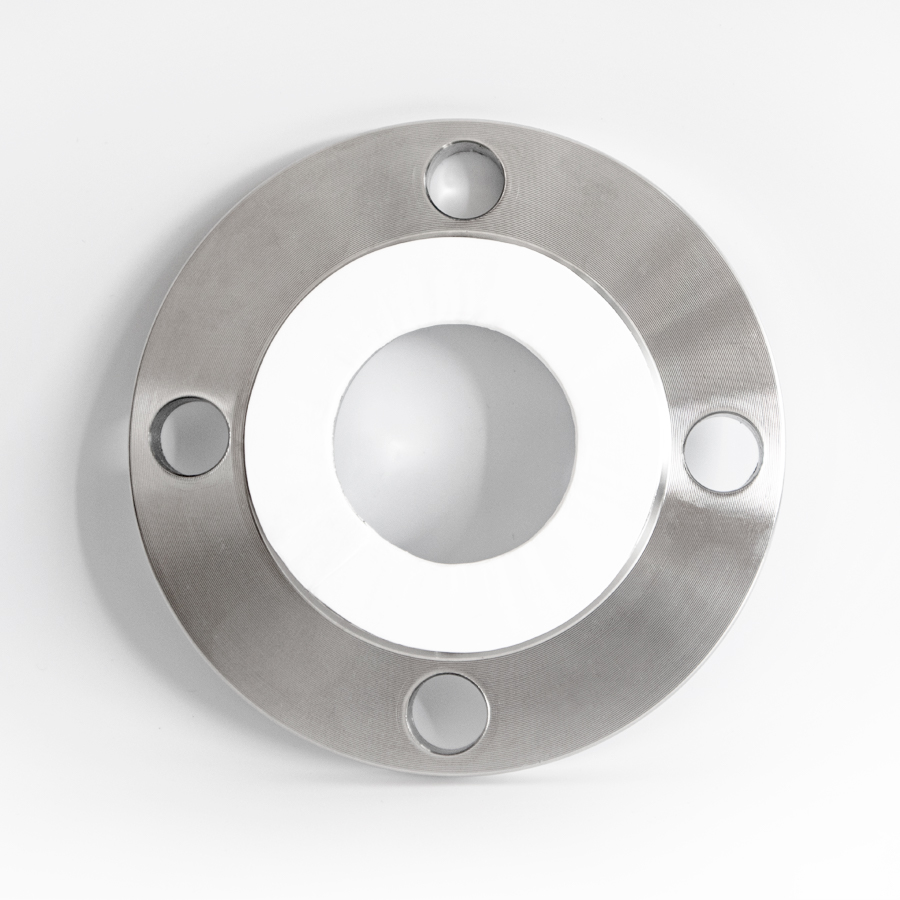

Sealing of misalignment or damaged flange.

Good compressive resilience property.

Excellent temperature stability.

Low diffusion leakage.

Good sealing performance.

Properties:

Excellent mechanical properties.

Excellent chemical resistance.

UV resistant; non-aging.

Nontoxic ;ensures high levels of cleanliness.

Applications:

Various types of flanges, oversized flanges.

Manholes, ventilation systems, inspection port.

Heat exchangers.

Pumps; compressor housing.

Chemical reactors.

Gas lines and food production systems.

Certificates:

GB 4806.7-2016

ISO 9001:2015